The design graph shown provides the possibility to show the deflections, which are obtained after installation and the deflections that occur after the soil has settled.

The graph has been obtained by analysing the results of the work carried out by TEPPFA on the performance of buried thermoplastics pipes. The project was carried out in the period 1996-2001. The results of this analysis were verified with results from other studies, including the results of measurements performed in operational sewers throughout Europe.

The graph is valid for:

1. Burial depths of more then 60 cm. The data used for evaluation were representing depths between 30 cm and 6 meter. It was shown that traffic load and depth are insignificant parameters. In other words they do not affect the pipe deformation. It only speeds up the settlement of the soil, meaning that the final deflection is reached within a rather short period after installation.

2. Soil types varying from granular to cohesive like clay.

3.Traffic load included.

The effect of traffic is included in the final deflection graph. The final deflection will always be reached. When traffic is present it will be reached in an earlier stage. When the soil has reached it's maximum density, no further increase of deflection will occur.

4.All thermoplastics pipes in the stiffness range of more than 2 KN/m2 at least fulfilling the ring flexibility test. Further they shall fulfil EN13476, EN12666, EN1852 and EN1401.

5. Sheet piles shall be removed before compaction, in accordance with the recommendations in EN1610. If however the sheet piles are removed after compaction, then one shall realise that the "well" or "moderate" compaction level will be reduced to the "None" compaction level.

6. Pipe diameters.

Up to and including1100 mm.

Up to this diameter deflections were verified. However, when applying the volume approach technique, it is found that the graph is also valid for bigger diameters.

The graph does not cover the use of big lumps of dry clay, which are dumped on top of the pipe.

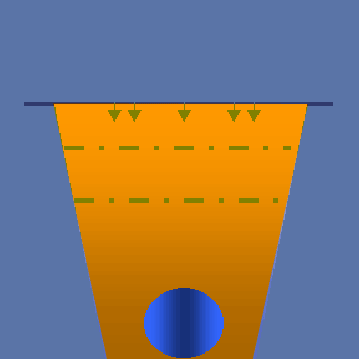

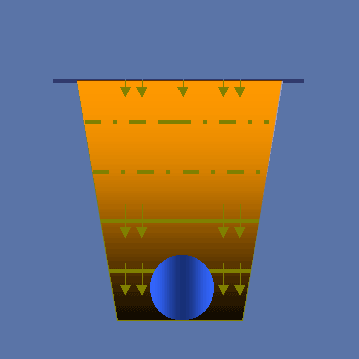

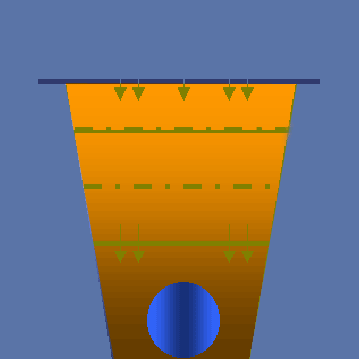

A moderate installation is achieved when a granular soil is placed around the pipe in shifts of 30-60 cm and then compacted.

Typical values of the density are between 95-98 % Standard Proctor

A well or good type of installation is achieved when granular soils are used. The soil shall be placed in layers of 30 cm and then compacted. The pipe shall at least be covered with 15 cm of soil before compaction is applied over the crown of the pipe.

The amount of compaction effort depends very much on the quality of the granular material. When so-called free floating materials are used, then hardly any effort is required. If the granluar material becomes more cohesive, like in the case of silty sand, more effort is required to obtain a good compaction.

A moderate installation is achieved when a granular soil is placed around the pipe in shifts of 30-60 cm and then compacted.

Typical values of the density are between 95-98 % Standard Proctor

It is recommeded to utilise always a 'well' to 'moderate' type of installation,in order to prevent subsidence of the street caused by the settlement of the soil after installation. It shall be realised that most of the effort and hence cost of urban pipeline projects are related to

instalation and street works.

The recommended pipe stiffnesses is in the range of 4 till 16 kPa, for reason that if an installation is performed less optimal as recommended, one still faces a reasonable low deflection.

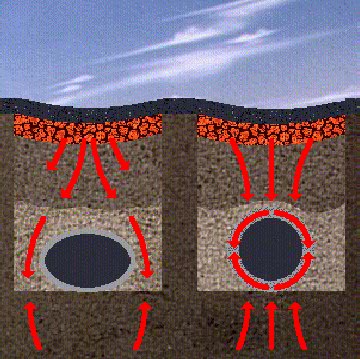

The accompanying picture shows that irrespective of pipe stiffness, subsidence of the street will occur due to the settlement of the soil

in case the soil is not compacted during installation